|

|

|

Question: Why do you need to clean tapes? THE PROBLEM: CLEANING For well over a quarter of a century computer tape users have known the importance of maintaining their magnetic media. Instrumentation and video engineers have also come to realize the need for tape maintenance as information-packing densities continue to increase. Intimate contact between the recording or playback head and the oxide surface of the tape is critical to good performance. When an instantaneous loss of signal (dropout) occurs it is usually caused by an imperfect contact between the head and the oxide at that point. Separations of only 7 millionths of an inch between the head and tape will often result in over 50% loss of signal (1 MHz @ 60 ips = 60m inch wavelength, spacing loss = 55 db per wavelength, Wallace formula). Research has shown that most dropouts are only 4 to 10 thousandths of an inch long, but just one in the wrong place can affect the integrity of critical and possibly irretrievable data. New tapes need cleaning because manufacturing (slitting) debris is left on the surface. New tapes also need burnishing because they are abrasive. The abrasiveness in this case is not from dirt but from the manufacturing process itself. Even dirty used tapes are less abrasive than new tapes; clean used tapes are better yet. Since a dirty oxide surface is abrasive, proper cleaning of both new and used tapes is the solution to reduce abrasiveness and dirt, and to give the best life expectancy to expensive heads. While manufacturing defects can sometimes cause imperfections in the oxide surface, contamination is the most common cause of performance problems. Some contaminants are elements of the tape's environment - dust, smoke, fibers, hair, fingerprints, cigarette ash, and alcohol residue. But most are from the tape itself - shedding oxide, fractured base film (mylar), and debris from slitting. About 80% of these contaminating particles are loose and can be wiped off to eliminate transient errors. The other 20% have become embedded, causing permanent errors and must be scraped off. |

|

|

|

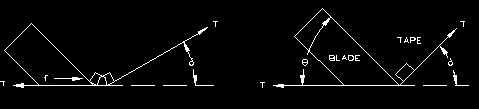

Cleaning Effectiveness Factor (C)=KT & ¸ q Vt |

Where: |

|

WINDING Cleaning alone will not guarantee the integrity of tapes; it must be coupled with precision winding. Long lengths of thin tape (i.e. 9200 feet x .001 inches and thinner) are susceptible to damage during shipping and handling. The Department of Defense devised a specification for conditioning tape prior to handling in order to preserve good physical characteristics. This specification, NSA L14-2, covers several aspects of winding including a precision stack and a stable pack. A precision stack leaves no protruding edges (scatter wind). It centers the tape between the guiding flanges thereby keeping the tape from rubbing against the flanges and wearing or curling the edge of the tape. Degaussing (erasure) and handling can also damage the edges of a non-precision stack. A scattered wind can contribute to skew on the tape recorder. This is why cleaning and precision winding is so important before use, degaussing, storage, or transporting. A tight pack inhibits lateral shifting that can occur from shock or vibration because trapped air has been removed to improve layer-to-layer friction. A stable conditioned pack inhibits longitudinal shifting which can occur from changes in temperature and humidity. Normal winding, that is winding with constant tension or constant torque, is insufficient for conditioning because it produces areas of negative tension in the tape pack resulting in poor layer-to-layer friction. This can cause microscopic shifting which degrades tape performance. If allowed to advance, it will cause cinching and permanent damage to the tape. THE SOLUTION: Contaminants and poor winding cause considerable damage to expensive magnetic tape. BOW Industries protects your investment by eliminating these problems. HERE'S HOW! CLEANING AND BURNISHING The BOW sapphire blade provides superior removal of embedded dirt particles and smoothes abrasive oxide surfaces of new tapes. This very hard gemstone blade has a long life and is resistant to nicking and wear grooves from the tape. The BOW tissue stations are positioned upstream of the blade to remove loose dirt, and downstream to remove dirt loosened by the blade. Designed for maximum efficiency, the tissue stations maintain a firm contact point with an optimum radius. The tissues are made of special non-shedding long filament nylon fabric that is automatically advanced, allowing clean tissue to always contact the tape. PRECISION STACKING (Reel to Reel Tape Only) The BOW packwheel permits precision guiding of one layer on top of the preceding layer. To be effective this wheel has a firm support, a large diameter (over 6"), 180 degrees of tape wrap around it, and engages a reel that is also firmly supported. The packwheel's "air squeegee" affect prevents the air from affecting the wind so there is good layer-to-layer friction to prevent shifting in the pack; this is necessary to prevent a scattered wind. The BOW hubs insure precision locating. The hub holds the reel firmly for precision stacking and insures parallel positioning with the tape deck. The hub also has a positive locking feature that gives an over-center single movement action and an automatic adjustment for variations in reel-hub thickness and chamfer. ACTIVE GUIDING (DIGITAL CASSETTES ONLY) Active guiding has been the subject of many discussion and experiments. It has long been recognized that flanged guides if not properly aligned will cause significant edge damage. Further, poor tape stack quality has been traditionally solved by the use of a packwheel that removes air between layers of tape to provide a "precision" stack of the tape. Use of a packwheel is not possible with digital cassettes. BOW Industries’ "active guiding" system will provide a uniform tape stack by simply sensing where the tape is coming out of the cassette shell and making minor corrections to guide the tape through the tape path and onto the other reel. PROGRAMMMED-TENSION WINDING Using empirical data derived from research, the government developed a programmed tension winding system that protects against longitudinal pack shifting aggravated by shock, vibration, temperature, and humidity changes. Systems developed by BOW Industries conform to this profile. Virtually every major tape rehabilitation center uses a programmed-tension winding system on instrumentation tape prior to returning the tape to service. It is the only known method of meeting government defined temperature/humidity cycle requirements for 1/2 and 1 inch instrumentation tape. TESTING The benefits of tape maintenance are dramatic when demonstrated through magnetic certification of the media performance. Flexibility is the key to BOW's testing systems that duplicate the recording systems demands on the tape and provide meaningful dropout information. BOW Industries' system for cleaning, precision stacking, and programmed-tension winding is essential for eliminating costly dropouts and promoting safe archival storage.

To see how BOW can save you time and money call (703)361-7704 to talk with one of our representatives. He will gladly write an analysis of your company's needs and how BOW Industries can fill them. |

|

|